Thousands of local and international businesses benefit from the reliability and efficiency afforded to them by their rotary screw compressor systems.

National Air Compressors stock, supply and service a range of quality rotary screw compressors by BOGE for the best of German engineering. Our partnership with BOGE means that you benefit from Service + Reliability.

With offices in sydney and brisbane we offer a complete compressed air solution from a compressed air audit to accurately identify your compressed air requirements to the sale of a suitable screw compressor solution and ongoing scheduled servicing to ensure that your business operations can depend on a reliable and cost effective compressed air system.

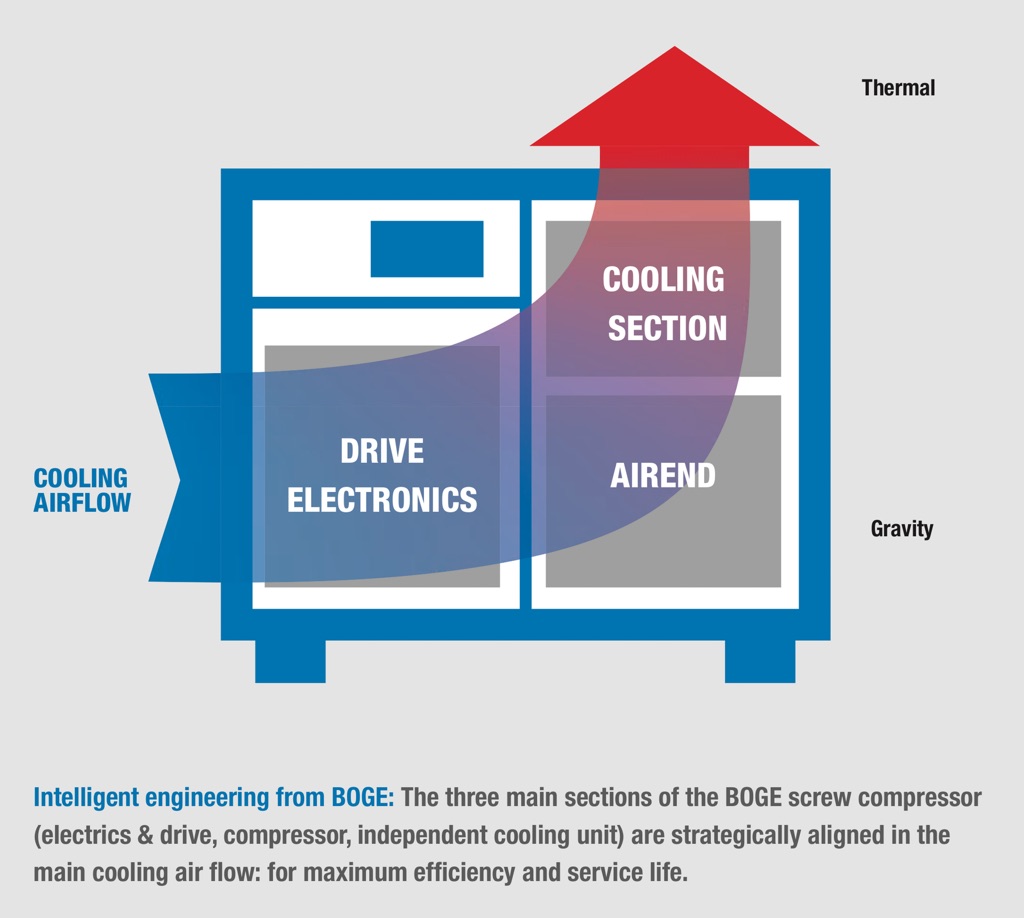

BOGE engineers harnessed this simple law of physics in order to make BOGE screw compressors even more efficient and to prolong their service life. Cooling air is taken in at the lowest point in the package by a sperate cooling air fan and is drawn over the compent parts upwards before leaving the compressor at the highest point - a so called chimney effect. The main cooling air flow is many times higher than actual cooling air flow of the integrated motor fan. Due to the chimney principle, the system keeps cooling vene during load reversal.

The intake filter is positioned in the coolest part of the cooling airflow and takes in the air for compression at the lowest temperature. This results in an optimised volumetric efficiency and output from the compressor. The air/oil cooler, on the other hand, is poitioned at the top of the compressor station. The cooler is generously dimensioned and, in conjunction with the cooloin airflow, provides the lowest possible internal cabinent temperature as well as discharged compressed air temperature. When connected diretly to ducting, the cooling air can be removed without any problems or recovered and easily redirected to supplment space heating.

Motor, switch cabinent and all electrical componenets are positioned at the intake of the main cooling airflow and benefit from the coolest air. As a result these components do not overheat either in load or idle mode which means their service life is extended considerably. There are no heat sinks within the cabinent in either operating mode.

BOGE engineers have positioned the oil pre-separator horzontally at the lowest point of the system. Also due to rapid reduction of the compressed air speed after compression bulk oil "rains" from the comresed air into the reservoir - a most efficient form of oil pre-separation.

The BOGE oil separation system is designed to minimise internal pressure losses and to ensure a residual oil content of 1-3 mg/m³ in every operating phase. The horizontal combi-tanke ensures a low foam level at load reversal virtually eliminating the risk of bulk oil reaching the separator cartridges.

BOGE oil separator cartridges have a long service life - not only as a result of the highly effective oil pre-separation but also because of the large safety distance between the oil surface and the separator that prevents the oil from mograting into the separator cartridge.

Type your best E-mail Address